There is a lot of work done by the engine for your vehicle. Your car wouldn’t be able to move without the engine, which is why it is important to ensure it is clean of debris, grime, and dust. The filters will start getting blocked over time, insects find their way into the vehicle, and leaves and dirt blow under the hood. Grease covering the engine traps heat, which makes it harder for the engine to cool properly.

Vehicles' vital fluids normally perform two important functions: lubricating and cleaning. As the fluid circulates through the parts, it gathers the dirt and metal shavings that can accumulate over time. If you’re lucky, this debris will settle on the bottom of the pan or housing and not circulate through the system. That’s why some auto shops use machines that perform a transmission fluid flush, ensuring that more of this debris is removed before any new transmission fluid is poured into the vehicle.

Nothing prolongs vehicle life more than regular fluid changes. In automatic transmissions/transaxles, the recommended service interval is about every 30,000 miles or 30 months. (Check your owner’s manual or service manual for your car’s specifics.) The automatic transmission fluid (ATF) should be changed sooner if its dipstick reveals dark or burnt-smelling fluid.

Changing Engine Oil Can Make a Lot of Difference

If you can garner some initial patience, learning how to change automatic transmission fluid will only benefit you in the long run. More importantly, you’ll need an automatic transmission filter kit; they normally contain a gasket for the pan in addition to the new transmission filter and its O-ring. Along with some basic shop tools, you’re ready to get started.

Step 1: Transmission fluid drains better at operating temperature, so let your car idle for a few minutes first. After turning your ignition off, raise and secure the vehicle. Then, lay down a tarp, some cardboard or a newspaper under at least a two-gallon catch pan. Next, remove the bolts from one side of the transmission pan, being cautious of hot exhaust parts and fluid.

Step 2: Gradually loosen the other bolts, which should allow the pan to tilt and begin to drain. Once all bolts are removed, lower the pan and dump the remaining fluid into the catch pan. Gently break the gasket seal with a screwdriver, if necessary.

Step 3: Clean the gasket surfaces on both the pan and the transmission housing. Inspect the pan for metal shavings or other signs of internal damage, and then clean it with solvent.

Step 4: Remove the old transmission filter and O-ring. The filter contains fluid, so keep the drain pan underneath.

Step 5: Install the new transmission filter, making sure that its O-ring seats in the appropriate orifice.

Step 6: Attach the new gasket to the pan with oil-soluble grease –not gasket sealer or adhesive.

Step 7: Refer to the service manual about using thread sealer on any or all of the transmission pan bolts, then screw in all fasteners finger-tight.

Step 8: Torque the pan bolts to spec in a spiral pattern starting at the center. Maximum torque is often about 12 pounds per foot.

Step 9: Lower the vehicle and fill the transmission with the recommended amount of fluid.

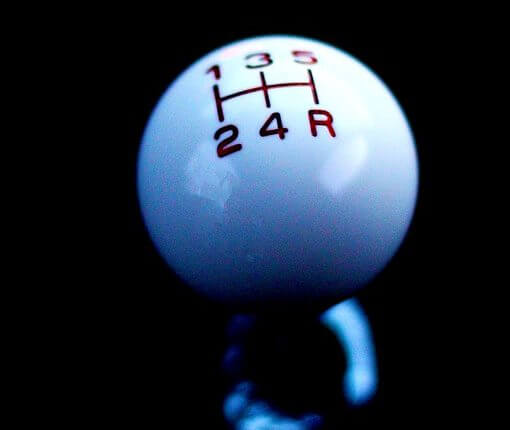

Step 10: Start the vehicle, warm it up, then shut it off and check for leaks. If you don’t detect any leaks, run the vehicle up to operating temperature on level ground, move the shifter through all gears, return to park and check the dipstick while the engine idles.

Always practice good safety behaviors when working on motor vehicles. To help prevent injuries, use appropriate personal protective equipment, which may include safety gloves, goggles, helmets and shoes.

CEO at Euro Team Performance